DS-7CP Flow-Through Cell

Product Introduction:

The DS-7CP flow-through cell system consists of a storage tank for storing the dissolution medium, a pump for transporting the dissolution medium, a flow tank and a constant temperature water bath to maintain the temperature of the dissolution medium. The flow-through cell is a new dissolution detection method, which is included in the United States Pharmacopoeia, Chinese Pharmacopoeia, European Pharmacopoeia and Japanese Pharmacopoeia. Widely suitable for the study of the release rate of various dosage forms such as insoluble formulations, sustained-release and controlled release formulations, microspheres, suspensions, liposomes, soft capsules, suppositories, semi solid formulations, etc.

Main features:

1. Classification

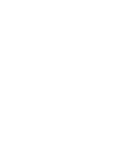

① Open System

Open system is an open circulation pool method. The dissolved medium is sampled at a time point using an automatic sampling device after passing through the flow tank. A large amount of fresh dissolved medium continuously flows through the tested sample, allowing the solid to come into contact with the fresh medium at any time, gradually dissolving until it is completely dissolved. The dissolved part is promptly taken away from the flow tank, and the leakage conditions are maintained at all times.

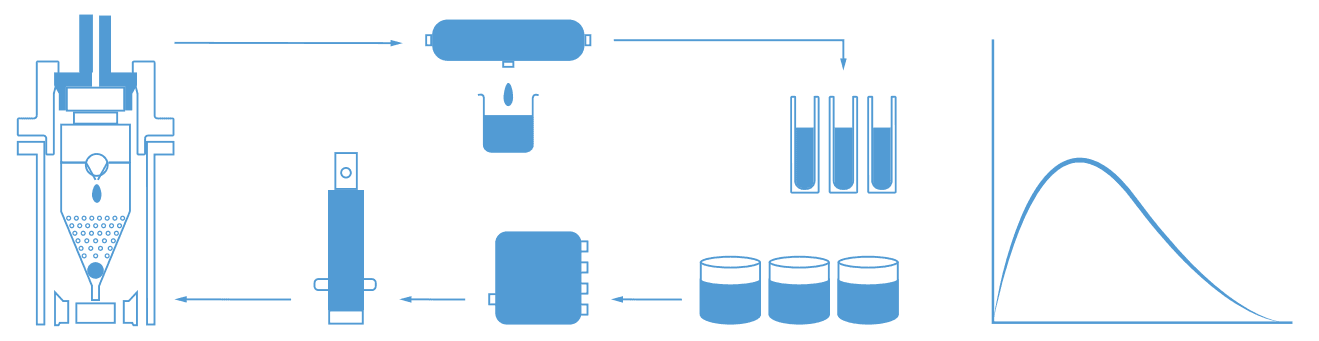

② Closed system

Closed system is a circulating flow pool method. Place the sample on a sample rack in a specially designed flow cell, preheat the solvent to 37 ℃, and pump it in with a constant flow pump. The solvent passes through a water bath equipped with a constant temperature device, enters the lower end of the flow cell, comes into contact with the sample, and flows out after being filtered at the upper end of the flow cell, returning to the solvent bottle. The sample is collected for analysis at a defined time point.

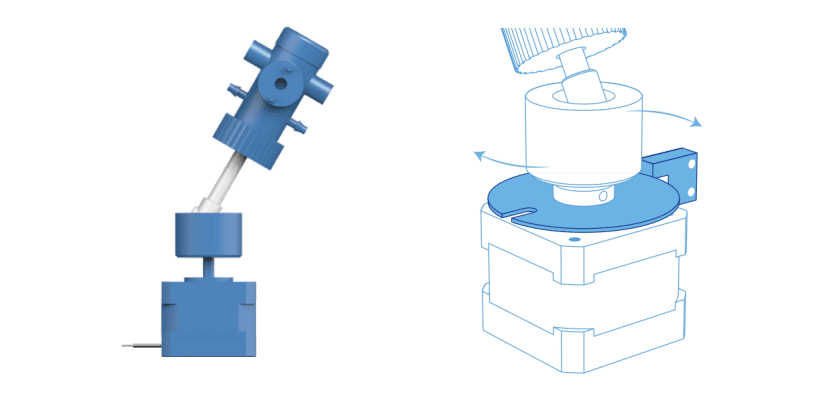

2. Multiple dosage form flow-through cell available

There are various types of circulation tanks, which can be suitable for various dosage forms and can be adapted to the same water bath jacket. The selection is flexible and the application range is wide.

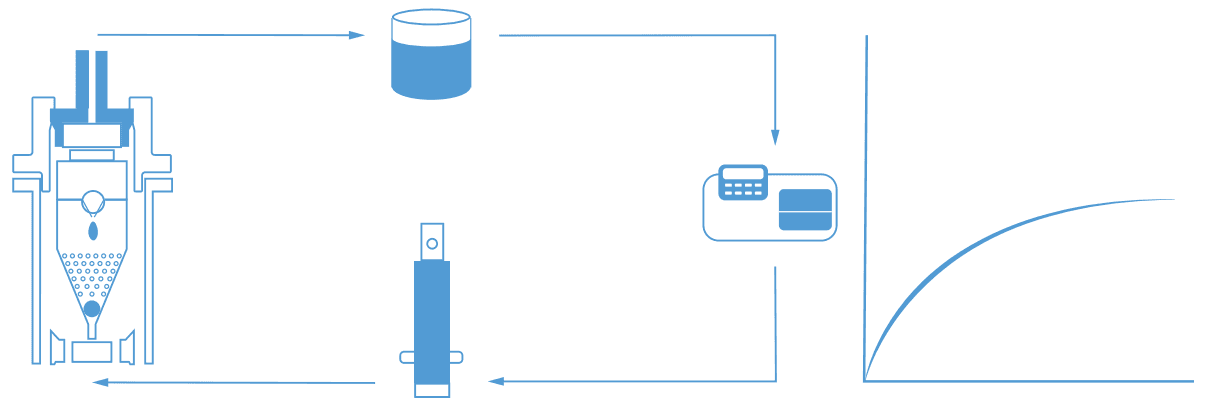

3. Piston Pump

① Pulse infusion is achieved through piston rotation.

② No valve body, no consumables, wear-resistant and high stability.

③ Seven piston pumps are independently controlled and the flow rate is independently adjustable.

④ Continuous and stable operation for more than 6 months, suitable for long-term formulations.

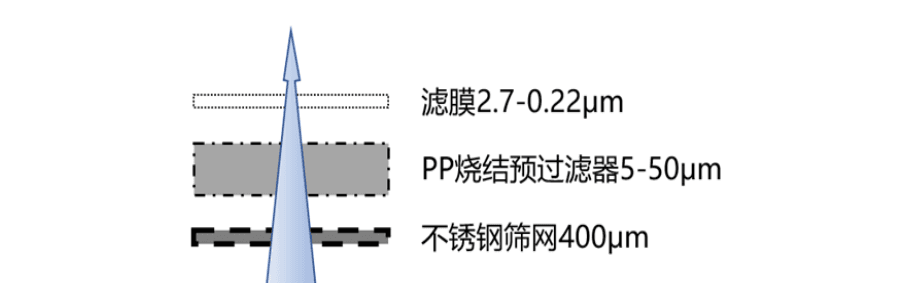

4. Filtering

① Real time filtration: All test sample solutions must be filtered in real time when flowing out of the flow-through cell (with a 25mm diameter filter membrane).

② Filter membrane selection: Select a filter membrane with appropriate pore size and material to prevent excessive negative pressure, but also to retain undissolved particles. It is recommended to use filter membrane materials such as glass fiber, cellulose, polypropylene, etc.

③ Pressure monitoring: The system back pressure generated on the filter membrane can affect the flow rate of the medium, thereby affecting drug dissolution. The Huarong flow pool method is equipped with a pressure monitoring system, which can monitor and record system pressure in real-time.

④ Multiple filtration: The Huarong circulation tank is designed with multiple filtration to ensure that insoluble particles are filtered step by step, reduce system pressure, and ensure accurate flow rate.

5. Flow Rate

① Flow rate affects dissolution: Flow rate affects the dissolution curve, which can accelerate or slow down the dissolution rate of the tested sample.

② Flow rate selection: Standard flow rates of 4, 8, and 16ml/min (USP&Chp: ± 5%), but flow rates can also be selected from 2 to 32ml/min.

③ High and low flow rates: Insoluble formulations generally use higher flow rates, while suspension microspheres and implants generally use lower flow rates.

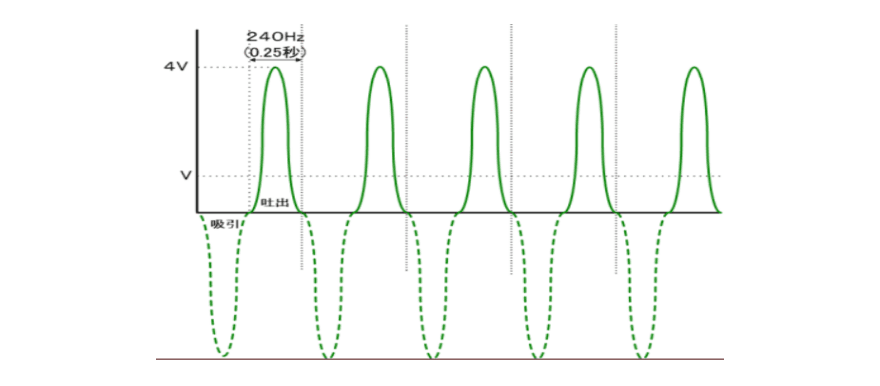

④ Flow rate pulse: The pharmacopoeia requires a sinusoidal flow rate curve, with a flow rate pulse of 120 ± 10 times per minute.

⑤ Flow rate optimization: Conduct flow rate research to optimize experimental results.

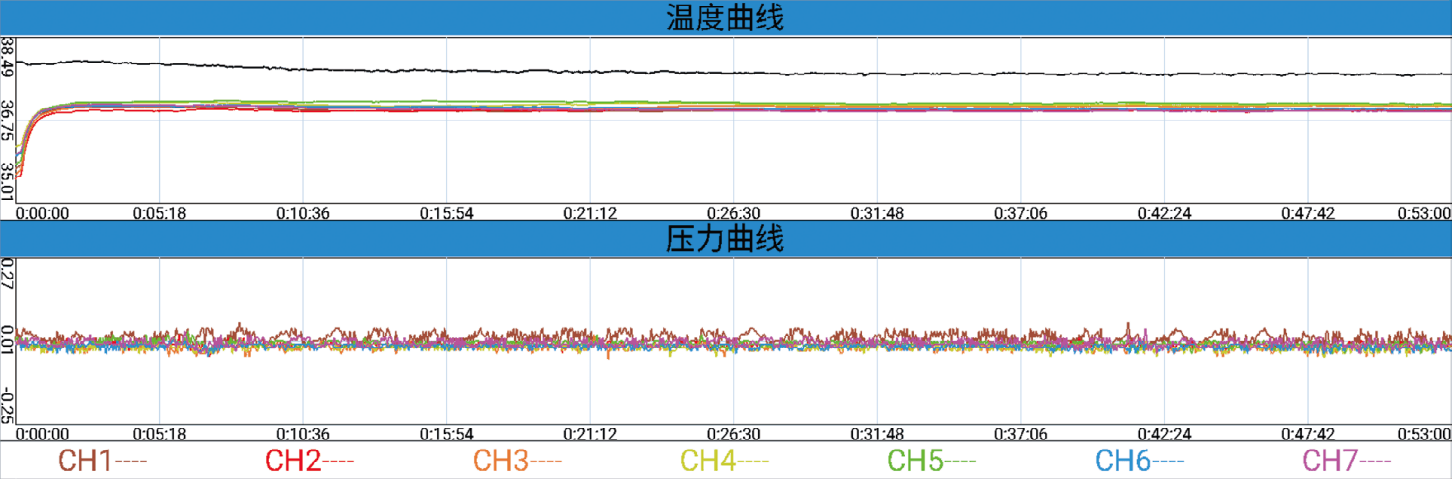

6. Temperature and Pressure Monitoring

① Real time temperature monitoring: Independent water bath and tank temperature sensors, real-time monitoring of temperature changes in the tank and water bath.

② Multi filtration system: Ensure that insoluble particles in the sample are filtered step by step, reduce system pressure, and ensure the accuracy of flow rate.

③ Real time pressure monitoring: Seven independent pressure sensors monitor the pressure of the tank in real time and predict the accuracy of the flow rate. When the pressure is too high, the pump is stopped to release the pressure warning.

④ Analysis of abnormal dissolution: Real time temperature and pressure monitoring, providing reference for the analysis of abnormal dissolution results.

7. Software System

① 8.4 inch touch screen control, Wahyong diffusion workstation, human-computer interaction, simple operation.

② Can configure 1000 accounts and 1000 experimental methods.

③ Paperless report management, capable of connecting to network printers, data can be stored locally and backed up to USB flash drives or enterprise servers.

④ Data audit tracking function, three-level permission management, in compliance with FDA 21 CFR Part 11 requirements.