Date:

Teacher Xie:

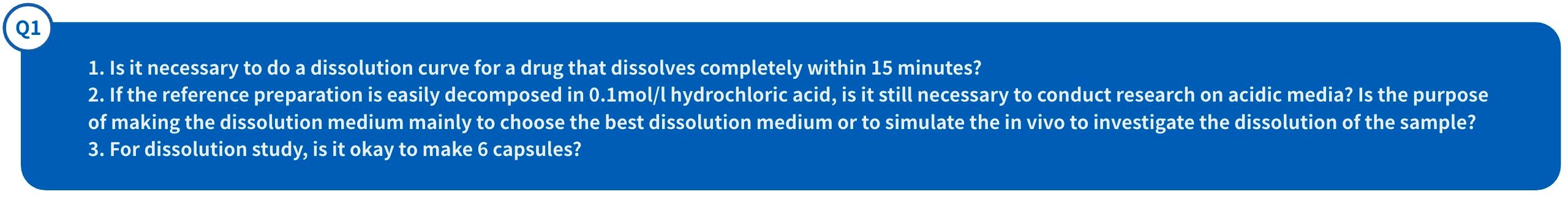

(1) need. But it only takes 5, 10, 15 and 30 minutes, because the platform area has been reached in 15 minutes and 30 minutes.

(2) When determining the solubility and stability of the API in each dissolution medium, if it is found that the API is unstable in a certain medium, the determination method can be considered as appropriate according to the degree of instability (i.e. degradation rate), such as:

Inject the sample immediately;

After all the principal components are converted into the "substance", the content is determined, and then the dissolved amount of the principal components is derived (the conversion coefficient of the two should be known);

The two were separated by HPLC and determined respectively. Convert the "transformation" into the principal component, and finally calculate the dissolved amount based on the principal component.

(4) The determination of dissolution curve has many functions and purposes, not only to establish three-dimensional internal and external correlation, but also to use such a means to "analyze" and "dismember" the internal quality of solid preparations!

(5) Many laws and regulations require 12 tablets, which is considered from the statistical point of view when the production scale reaches hundreds of thousands or even millions of tablets. As far as the actual production situation in China is concerned, 6 tablets can be used at both the R&D stage and the quality evaluation stage, and the measurement data are basically considered representative.

Teacher Xie:

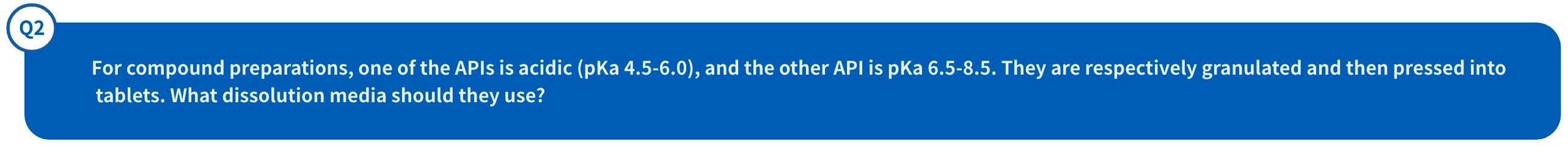

Hello! Nice to see your question. Suggestions are as follows:

(1) First, measure the solubility of two substances in different dissolution media, and observe the pH solubility curve between the vertical coordinates 4.5~8.0 (whether it is "steep").

(2) If it is flat, it can be studied with the usual four media; If it is steep, it is recommended to add the study of multiple dissolved media "between 4.5 and 8.0, every 0.5 interval", and then formulate the dissolved media in the quality standard according to the actual measurement.

Teacher Xie:

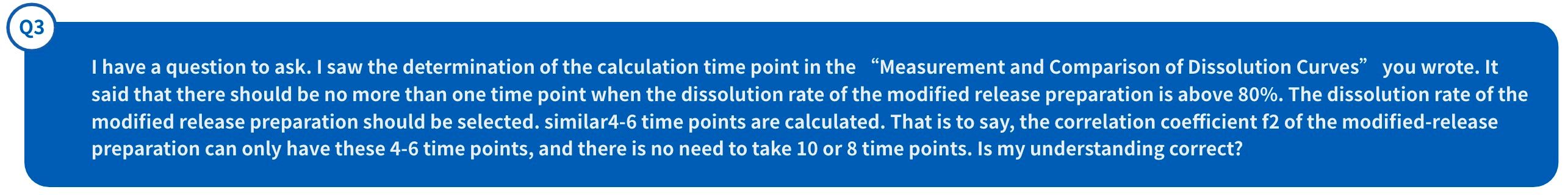

When calculating the factor f2, the contribution of n value is relatively large, and the value of n will be large, and the calculation result will be wrongly high. Therefore, the Japanese dissolution test guideline clearly stipulates that the n value shall not be greater than 6. It is suggested to try, what is the relationship between the observation results and the n value

Teacher Xie:

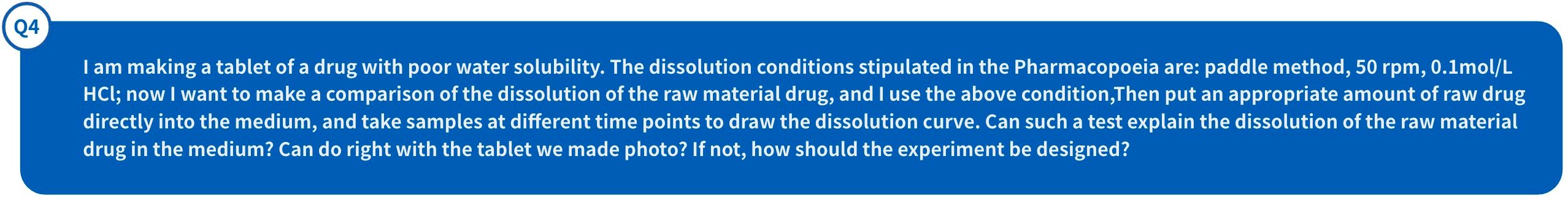

The dissolution curve of the drug substance can not be compared with that of the finished product. Its determination usually has the following two purposes:

(1) To evaluate the influence of API characteristics on dissolution, such as particle size, crystal form, particle shape, specific surface energy and other parameters.

(2) To evaluate the improvement of dissolution of APIs by intermediates made from different preparation processes/prescriptions/excipients. The above parameters were optimized and screened to lay a foundation for preparation research and development.

Teacher Xie:

Nice to see your question. The principle of this problem is discussed in detail in "2.2 Loss during filtration" in the article "No. 11 - Several problems to be noticed in dissolution determination" written by me. As there is an adsorption saturation process between the main components and the filter membrane after micronization of such small size preparations, and this process will be different due to different brands of filter membranes, even if the volume of discarded filter membranes and primary filtrate of different brands is verified, it is not possible to guarantee that various complex situations will be encountered during actual measurement. Therefore, "centrifugation" is recommended. The objection to this kind of treatment is mainly "the concern that centrifugation will lead to the continuous dissolution of the sample in the extracted liquid". In fact, the possibility of this probability is extremely small, and even if it exists, it will not have a significant impact on the actual measurement results. If you want to verify, you can use different speeds and centrifugation times to distinguish them, and observe whether they are increasing. Considering the above, I have seen many varieties of centrifugation method proposed in the quality standard in the drug inspection institute, so please rest assured! In fact, there is a more "skilled person is bold" approach: take it out and let it stand for a period of time to directly inject the sample (the tedious steps of centrifugation are omitted)! Because of the small size of the preparation, the probability of the excipient particles existing in the sample plugging the chromatographic column is extremely small. I have done this myself and during my study in Japan. After hundreds of injections, everything is safe. Don't believe it!

Teacher Xie:

All involved are the "methodological validation content" of dissolution determination method. Sometimes, we tend to complicate the problem. In fact, it is simple to operate as follows:

(1) Linearity test: 5 points (such as 10%, 20%, 40%, 80% and 120%) shall be designed between 10% and 120% of the dissolution amount to verify that the correlation coefficient is greater than 0.999; Of course, in the study of dissolution curve, the minimum dissolution is more than 10%.

(2) Precision test: measure the dissolution of solutions with concentration of 10%, 40% and 100% for 5~6 times respectively and calculate the RSD, which is less than 2.0%;

(3) Accuracy test/recovery test: prepare the control sample into five concentration solutions of 10%, 20%, 40%, 80% and 120%, respectively add the corresponding amount of excipients when the dissolution is 100%, and determine the recovery rate. The average recovery rate is 98.0%~102.0%.

(4) As stated in the Guiding Principles of Method Validation Technology, "If the limit range of the release is 20% after 1 hour to 90% after 24 hours, the validation range should be 0~110%", which is too theoretical and bookish, do not "copy mechanically"!

Teacher Xie:

It is recommended that you read the article "No. 5 - Determination and Comparison of Dissolution Curves" written by me in detail. The determination time is 2 hours in acidic medium and 6 hours in all other mediums. Steps to relax test parameters: first increase the rotating speed to 75 rpm/paddle method or 120 rpm/basket method, then increase the surfactant concentration to 3.0%, if still unsuccessful, then increase the rotating speed to 100 rpm (paddle method is used instead of basket method). The evaluation standard is not based on 70% in 45 minutes, but on the condition that the dissolution rate of two consecutive points is more than 90% and the difference is within 5%, the test can be completed ahead of time.

If the sampling time point in the quality standard is 60 minutes or 90 minutes, or even 120 minutes (there are many varieties in Japan), it is actually more demanding! Most of the quality standards in our country are formulated as 30 minutes or 45 minutes, which is "too low a requirement"! We also hope you can have a deep understanding!

Teacher Xie:

There is such a variety: it is qualified according to the dissolution test in the quality standard, but the disintegration time limit is unqualified. In fact, this phenomenon is very normal, as long as we know when the disintegration time limit and dissolution inspection should be formulated in the quality standard (please refer to the previous replies in this post and the content of the uploaded article), we can solve it... This product can be judged as "qualified"!

Teacher Xie:

According to the "Guidelines for Bioequivalence Test of Japanese Generic Drugs - Troubleshooting", when the reference preparation has dissolution delay lag, it is not necessarily necessary to compare the dissolution curve after using delay time correction, and direct comparison is also possible. However, the delay lag time difference between the imitation preparation and the reference preparation must be within 10 minutes.

Note Due to the large number of generic drugs in Japan, the Drug Administration of the Ministry of Health and Welfare of Japan has successively issued the Guiding Principles for Bioequivalence Test of Generic Drugs (mainly for solid preparations, including detailed dissolution research methods), the Guiding Principles for Bioequivalence Test of Oral Solid Preparations with Different Content Specifications, the Guiding Principles for Bioequivalence Test of Oral Solid Preparations after Prescription Changes (including other changes) Guidelines for bioequivalence test of solid preparations after dosage form change, and Troubleshooting of these guidelines. In the first half of last year, I translated the latest version (2007 version) of all the above contents, and added personal notes and interpretations, totaling 65000 words. The Drug Evaluation Forum, an internal publication of the New Drug Evaluation Center of the State Food and Drug Administration, published the Guiding Principles for Bioequivalence Test of Generic Drugs in the third journal of 2008. Please refer to the Guidance Principles for Bioequivalence Test of Generic Drugs - Troubleshooting for specific examples of using delay time to correct dissolution curves.

Teacher Xie:

yes. Visual observation shows that no solid particles are suspended during slight vibration. It is recommended not to use the method of "dissolving with organic solvent and then fixing the volume with dissolved medium". Instead, an organic solvent is dissolved and prepared into a concentrated solution of high concentration in a volumetric flask, and then an appropriate amount is precisely measured and diluted with a variety of dissolution media; At the same time, the concentrated solution can also be stored in the refrigerator for later use, so that "twice the result with half the effort" can be achieved!

The above content comes from the network and is only for learning and exchange. If there is infringement, please contact the editor to delete it.

Reprinted: Pharmacy