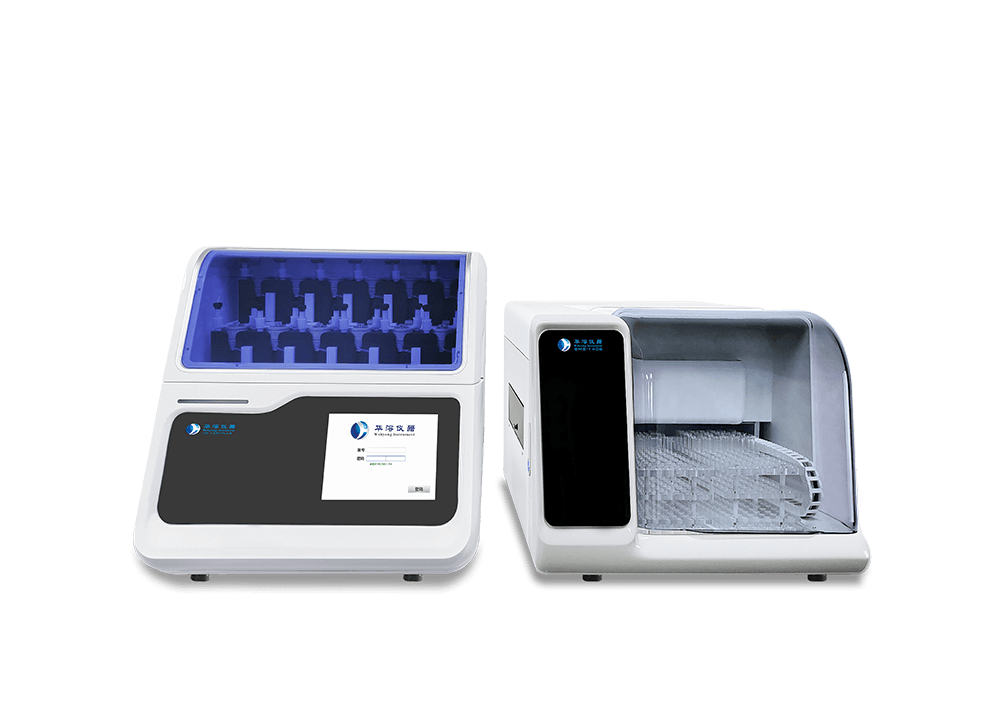

TD-12AT Transdermal Diffusion

Product Introduction:

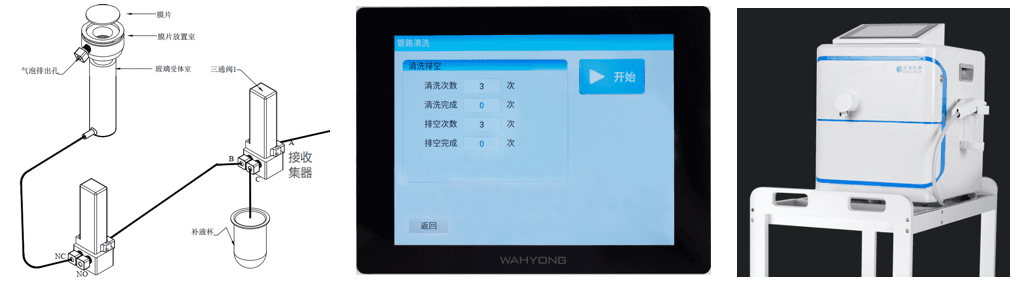

The TD-12AT automatic transdermal diffusion system consists of a diffusion host and a sample collector. The TD-12 transdermal diffusion host consists of two sets of 6+1 diffusion cells, with 6 diffusion cells used for diffusion experiments and the 7th diffusion cell used to monitor the temperature of the receiving solution. It meets the requirements of the US Pharmacopoeia and is a reliable and reproducible method for semi solid dosage form release determination. Mainly used for drug transdermal release tests of ointments, ointments, coatings, films, aerosols, and other formulations, to study the efficiency of drug penetration through the skin through a model of skin absorption.

Main features:

1. Temperature control

① The diffusion system adopts a dry heating method with high heating efficiency, and the temperature of the receiving and donor rooms is accurately controlled (≤ 0.2 ℃).

② The dual insulation design of anti evaporation cap and protective cover prevents solvent evaporation in the formulation and prevents the temperature of the diffusion cell and drug from being affected by the external environment.

③ Real time monitoring and recording of the temperature of the dry heating block and the receiving cell medium (independent temperature monitoring cell), and generating temperature curves.

④ Same temperature rehydration design to avoid the impact of rehydration temperature fluctuations on release or transdermal delivery.

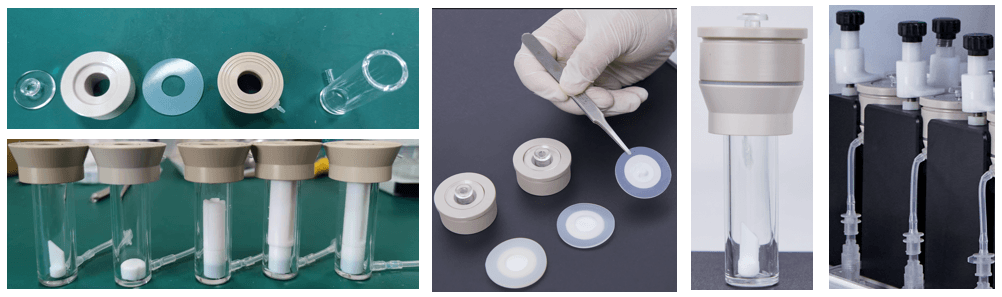

2. Selection of Transdermal Diffusion Cell

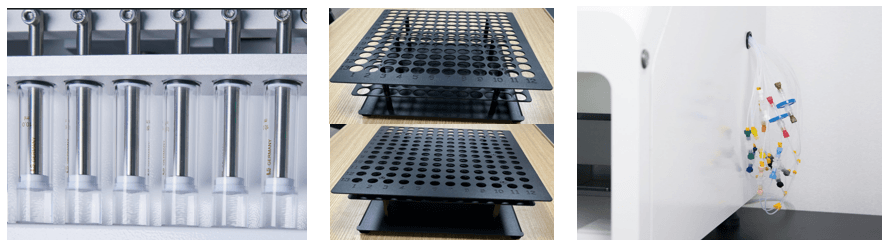

① Material: Improved Franz vertical diffusion cell, glass material, good heat transfer, fixed 1.77cm2( φ= 15mm) release area.

② Quantitative administration: Different thicknesses of quantitative loops allow for flexible control of different dosage levels.

③ Variable volume of diffusion cell: With different volumes of stirrers, the volume of diffusion cell can be flexibly changed.

④ Adaptive compression device: Spring+knob design, adaptive clamping and adjustment of the gap between the receiving room and the donor room.

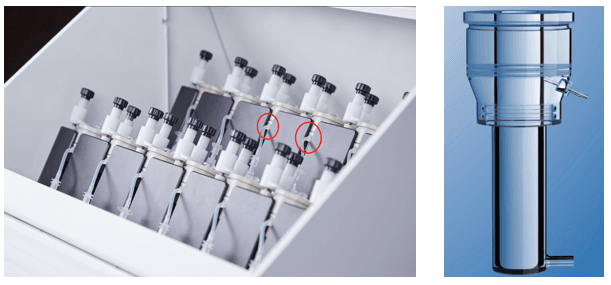

3. Automatic Exhaust Bubble

① Automatic exhaust design.

② The upper pipeline of the diffusion pool is used to eliminate bubbles.

③ Automatic sampling design, adding and absorbing media from the bottom of the diffusion pool, can achieve full flux sampling and partial sampling.

④ At the same time, the penetration test of 12 samples was carried out. The upper and lower groups were 6+6 (reference+self research), and different temperatures and mixing speeds could be set.

4. Flow path design

① Excellent flow path design, automatic lubrication of the pipeline before sampling, and automatic emptying of the pipeline after sampling to avoid cross contamination of the sample.

② 12 diffusion cells are independent media channels that can simultaneously conduct 12 sets of release media inspections.

③ After the experiment, automatically clean and empty the diffusion cell and pipeline system.

④ An online solvent degasser can be selected to degass the released medium.

5. Secondary Filtration and Precise Sampling

① High precision imported injection pump, which can achieve fast and accurate sampling with a sampling error of ≤ ± 1%.

② The sampler is automatically compatible with large test tubes (15ml) and liquid phase vials for sampling, with 36 sampling points.

③ The sampling system can perform online secondary filtration and can be equipped with an automatic membrane changer.

6. Software System

① 8.4 inch touch screen control, wahyong diffusion workstation, human-computer interaction, simple operation.

② Can configure 1000 accounts and 1000 experimental methods.

③ Paperless report management, capable of connecting to network printers, data can be stored locally and backed up to USB flash drives or enterprise servers.

④ Data audit tracking function, three-level permission management, in compliance with FDA 21 CFR Part 11 requirements.